Waterborne Output Optimisation

The client is a leading global supplier of liquid and powder coatings, supplying to manufacturers such as Volkswagen, Mercedes, General Motors and BYD. They specialise in waterborne paint products, and their aim within this project was to increase their production output in order to meet higher demand.

P7 were engaged to assist in the optimisation of the production output due to their focus on involving team members in the process, aligning with the P7 principle of “People + Process = Performance” – working closely with two key stakeholders from the company, the Area Manager and Area Process Engineer.

Before the project, the Client published a weekly production schedule that often resulted in conflicting requirements, such as:

- Small batch runs required more filling machine change-overs for containers and/or labels;

- More time had to be spent washing filling machines between assorted products because of multiple small batches;

- Production run splits required multiple change-overs for labels;

- Container sizes and types were not optimised, which caused frequent switching back and forth between different containers; • Frequent switches back and forth between scheduling the same two types of products;

- Multiple small batches of the same product being made each month, instead of making them at once with optimum batch sizes; and

- Plans having inaccurate run rates for filler based on the can size, which led to batches being allotted more time than necessary.

On top of this, minor machine stops and delays were frequent, which meant that production output rarely met demand.

These conflicts lowered production output, resulting in monthly back-orders to customers ranging from $250k to $1MM. The persistent back-orders jeopardised the area’s monthly production goals. Exacerbating the problem further was an order pattern by one customer, who would place large orders at the month end that consume large quantities of finished goods above forecasted amounts, requiring “drop-ins” of critical production orders.

Analysis of planning data and production history found:

- • 10 product codes historically produced an average 103 batches per year that can be targeted for batch size optimisation.

- • The planned filling machine run rates were found to be underestimated by 30-60% for 3.5L, 1L, and 0.5L containers.

- • KPI tracking data indicated that time allotted to machine change-over was excessive, relevant to the production plan of batches loaded and filled.

In order to overcome these challenges, P7 helped design and implement a solution to consolidate batch sizes for all work centres within inventory carrying limits, and to adjust the planned run rates to more realistic values for 3.5L, 1L and 0.5L containers.

Analysis was conducted on product codes and corresponding mixing tanks in order to adjust batches to appropriate sizes based on historical demand. Planning data for run rates was also updated in OMP and forecasting modules.

In order to drive continuous improvements from KPI tracking data, 3C Practical Problem Solving was used. Leadership Standard Work [LSW] was also developed with the Area Manager in order to ensure appropriate efforts are being applied to performance tracking, problem solving, and escalated issues. P7 also introduced a Scrum Board Project Management Tool to help teams visualise project steps and milestones, and drive efforts towards completion.

Additional work was completed to support the increase in uptime. This included repairs and upgrades to the filling machines, refurbishments to the labelling machine, and change-over analysis on the packing machine.

As a result of support from P7, the client has achieved:

- 38% reduction in annual batch quantities

- Increased capacity for filling machines by 590 units’ p/h

- Batch size optimisation; reducing both wash time and change-over time – resulting in increased filling machine uptime

- Revised KPI tracking metric – meaning captured performance and causes of abnormalities

- Record output of 86,503 gallons achieved, due to increased filler uptime

Achieving Operational Excellence

Our client, based in Germany, is part of the leading global supplier of liquid and powder coatings. Their goal was to ensure a reproduceable, sustainable operating system that would yield provable results, and could be spread out globally within just a few years.

Project7 [P7] were selected as the preferred support provider because of their known ability to involve people in projects, aligning with the P7 principle of “People + Process = Performance”.

With many ongoing acquisitions, it was important to the client to have a common operating system that could be used to align new sites with the existing sites.

Our clients site in Germany was chosen as the pilot site, as it is the largest of all their manufacturing sites, accounting for approximately a quarter of their yearly income.

Both onsite and on a global level, there were two main challenges: to demonstrate that the Operational Excellence Programme would work, both to the people within the site and as proof of concept to other manufacturing sites globally; and to cope with increasing demand from the Germany site.

On a local level, paint volume needed to be significantly increased using only the existing time, people and production lines. In total, 2000 tonnes of additional paint needed to be produced annually, approximately a 20% increase in production.

Additionally, the process for setting priorities in production planning was unnecessarily complicated, and workplace organisation had unclear responsibilities and was failing follow-up assessments.

Key to the Clients Operational Excellence Programme was the focus on engaging people using structured processes, such as problem-solving at the basest levels, to improve processes and overall performance.

The AOE system emphasises the use of three basic methods:

- Daily Tiered Visual Performance Management [TVPM]

- 3C problem solving – Concern, Containment and Countermeasure

- Leadership Standard Work

Additional tools and methods were also employed, including scrum meetings to drive continuous improvement, and lean tools such as Quick Changeover, Overall Equipment Effectiveness, 5S Workplace Organisation, autonomous maintenance and VSM.

On a site level, the pilot implementation was started in one of the Paint production cells, Paint 4, at level 1. Next, The Operational Excellence Programme was employed at level 2 with the Tiered Visual Performance Meeting with the production manager and the leader of the pilot area. Once the basics of the Operational Excellence Programme were in place in Paint 4, the team worked on ensuring their sustainability in the pilot area, and to agree the right concept was in place before rolling out to the rest of the plant.

Once this proven sustainability was in place, the roll-out of Operational Excellence Programme to the rest of production, and later to support functions such as Maintenance, was continued.

For the pilot implementation, a 5-day diagnostics workshop was conducted at the German site. The focus was chosen to be Paint 4, which delivers activators, thinners and clear coats. This area had previous exposure to prior production systems, and needed an increase in volume of nearly 20%.

It was later identified that the 5-day workshop could have been carried out in less time, however, this timeframe allowed the client to gain thorough insights into production flow – away from an otherwise busy daily routine.

The workshop enabled the set-up of clear Key Performance Indicators [KPIs] and brainstorming sessions which gave focus to important priorities and potential issues. This ensured problems could be resolved before escalation, while improved communications between teams encourages a greater sense of team morale.

As a result of support from P7, more than 1000 improvement opportunities were identified by the teams involved, while more than 40 financially-calculable quickwins were found.

The Client has since benefitted from;

- €1.3million+ in cost-savings

- 70% reduction in backorders

- Improved Puttie manufacturing process

- Weekly production targets exceeded

- Improved team culture

- Reduced downtime and cycle time; leading to OEE improvements across multiple cells

Now the Operational Excellence Programme is in place, there are:

- 25 Level 1 – 3 boards with daily meeting introduced

- Daily problem solving meetings for all major categories [SQDIC+P]

- Commitment and ownership by all involved employees

The TVPM structure allows for consecutive meetings from the shop floor level to the site management level within just a few hours, which was especially useful for speeding up the clients processes. This means that the client is now able to support the increased demand.

Pilot area, Paint 4:

Working with Operational Excellence Programme in the pilot area has resulted in a 19.3% increase in volume compared to the year before.

On the bottleneck line in Paint 4:

- 85% reduction in weekly downtime

- €90,000 annual savings in prevention of weekend overtime

- Annual capacity increased by 575,000 litres/year

- 70% reduction in backorders within 5 weeks of on-time deliveries

Practical Problem Solving and Kata Coaching

De La Rue provide government and commercial organisations with products and services that allow countries to trade, economies to grow and people to move securely around an ever-more connected world. These products include banknotes, passports and secure product identifiers. De La Rue employs 3,230 local employees, providing specialist in-country knowledge and expertise in 24 global locations and manufacturing facilities across 4 continents.

One of these manufacturing facilities is the Debden site. The site prints approximately 1.3bn of the 7bn banknotes produced by De La Rue every year. The site’s in-house Operational Excellence structured framework has delivered several improvements to how the site functioned over the past 3 years, but found that problem-solving capabilities were a weak link. De La Rue employed Project7’s services in order to improve their approach to problem-solving.

The key stakeholders for this project were the Debden site management team.

The site’s biggest problem was that there was no clearly defined approach to problem-solving and management.

The site lacked a standardised methodology, which caused shallow problem-solving such as firefighting and troubleshooting, leading to repeat occurrences.

Furthermore, there was no leadership coaching capability in place to support problem management. Approaches to problem-solving were more directive than questioning, and didn’t challenge problem understanding, which led to a lack of learning and understanding.

The management team required support regarding their role in problem-solving and in the coaching of their teams. This overall lack of a clear structured system, led to a lack of problem resolution, with only containment measures being put in place, rather than a fix for the root causes. This was impacting the management team, as they were heavily involved in problem-solving rather than assuming a coaching role with the process teams.

By engaging with the site’s leadership team, Project7 developed and integrated a practical problem-solving system and methodology, in which the onsite management team could define and improve their approach through “Improvement Kata” coaching and development of their teams.

Initial steps for the implementation of these systems were:

- Development of a problem-solving mindset towards learning, as well as solving problems through understanding people’s critical thinking

- Introduction of the concept of systematic problem understanding and countermeasure experimentation, rather than relying on a single action fix

- Coaching of problem-solving thinking through the management team who can review, process confirm and challenge the way of thinking

- Training the Kata improvement and coaching process so that it could be applied to the management team’s daily routines and standard diary

Implementation was split into 3 phases:

Phase 1: Problem Management

- The management team’s role in terms of site problem-solving was determined. Nine staff were identified and trained and verified in a Nine Step Problem Solving methodology. A site problem management system was also introduced to govern the approach and process confirm.

Phase 2: Kata-based Gemba

- The team were trained and coached in Kata coaching and Improvement Kata, leading to the implementation in the Print area to develop critical thinking, which was used as part of a Katabased morning Gemba walk.

Phase 3: Learning Through Experimentation

- The Kata routine coaching plan was developed further to include carrying out observations of the management team’s onsite coaching and feedback. A go-look-see methodology was also introduced as part of problem-solving. This led to a development of a Kata-based A3 methodology to apply experimentation to improvement projects.

The impact these new approaches to problem-solving had to performance within the facility included:

- £5.3M site savings through 9-Step problem-solving and Kata coaching, since implementation

- Examples include inventory reduction, £5 polymer spoil reduction, ink utilisation, £10 polymer BPS model adaptation.

- £1.1M site cost avoidance – again, through 9-Step problem-solving and Kata coaching implementation

- Examples include £10 polymer spoilage and cut registration mitigation.

Agile Product Design & Engineering

Our client’s task was to design, test, and implement a performance improvement modification package, in order to mitigate potential additional costs through compensation payments for technical issues, breach of contract, or any other operation “shop visit” costs.

These potential costs can be substantial, and in order to avoid incurring them, the client needed to complete the programme in roughly half the time a similar programme would take.

According to a high-level estimate, the financial benefit of reducing the expected programme duration was estimated to be around $3.2 million (£2.6 million) per week.

P7 were engaged to assist in the optimisation of the production output due to their focus on involving team members in the process. This is an essential element of the P7 principle of “People + Process = Performance”.

The client’s main challenge was that their in-service product was not achieving the targeted design cycles, which led to increased maintenance at shorter intervals, leading to an increase in costs.

Additional costs were incurred from contractual penalties whenever time on wing requirements were not met. A previous Master Project Plan, based on benchmarking to similar programmes, overran by 24 months, and ended with limited understanding of the overall programme impact.

Additionally, there were no controls over the loading of tasks to teams or team members, meaning there was no way to measure efficiency or contribution. There was also a lack of transparency within the design and engineering environment in terms of priorities, performance and status, and an overall lack of understanding and control of cross-department interdependencies. There was an issue with the disparity with understanding between teams, and contribution of each team over geographical locations.

The client’s objective was to provide a solution that addressed these problems, whilst developing a new approach to programme management, and a resulting culture shift that could be adopted by other priority programmes.

There were 3 steps to the solution P7 developed with the client:

Step 1 – to analyse and challenge the existing project plan, in order to bring the project cycle within the contractual timeframe.

Vertical Value Stream Mapping [VVSM] facilitated working sessions with the integrated project team in order to identify the major decisions to be made, and to increase right-first-time capability whilst reducing lead time. The aim was to optimise learning in the early project stages in order to reduce risk throughout the project life cycle.

Value Stream Analysis identified and prioritised the components that drive the project completion date back, and to analyse and challenge the current planning to create tangible lead times for product testing and manufacturing. It also enabled us to identify non-value adding process steps and eliminate idle time.

An Integrated Master Schedule [IMS] was developed for team-level planning. Links to related activities were provided, and critical pathways were defined. Planning platform P6 Primavera was introduced, and the milestones were linked to the defined activities to create the planning rules framework.

Rolling Wave “Sprint” Planning Cycles enabled more granular planning over Sprint periods, making it possible to define tasks by teams and individuals on a daily basis. This planning cycle also has the additional benefits of regular alignment and calibration of the complex team structures. Teams have full inclusion and responsibility within the Sprint cycles.

Task Allocation and Management using LeanKit was also implemented, wherein tasks are assigned to the individual and linked to the broader team, and can be managed in several ways including start date, due date and hours forecast. This enables work loading and levelling, which contributes to the overall requirements.

Data can be extracted from both Primavera and LeanKit to support the performance management of the project from a micro to macro level. The integration of project plans and tasks into digital platforms supported the global alignment, inclusion, and management of the project teams.

Step 2 – to design and implement the Management Operating System [MOS] to engage and lead the teams towards achieving the project objectives on time.

Tiered Visual Performance Management [TVPM] created a place for candid conversations. The project objectives are cascaded in the TVPM, alongside associated KPIs, both vertically and horizontally within the project organisation. Daily progress reviews were conducted with individuals, teams and departments. Project status at a glance made identifying delays, inhibitors and priorities transparent, as well as supporting action, responsibility and timing. The TVPM also instilled accountability through all organisational levels.

An Escalation Procedure was implemented, in which escalation triggers were defined in order to better recognise raise and respond to abnormalities.

A Standard Diary for the project calibrated and aligned the governance structure throughout the project team structure. The Diary included meeting structures in order to optimise overall meeting efficiency.

Process Confirmation created leadership habitual confirmation routines in order to provide regular opportunities for go-look-see, employee engagement and coaching. Vital elements that are critical to programme success were confirmed on a team rotational basis.

The LeanKit task hopper fed into the TVPM system, which was linked to the planning Sprints and IMS. The teams met daily to allocate tasks form the hopper and measure the task burndown during the Sprint period. The KPIs within the system also accounted for quality and people measures.

The TVPM platform was the foundation for leadership to influence behaviours, expectations and deliverables within the company.

Step 3 – to coach and mentor the project and programme managers in how to use the MOS system

effectively. This was done using the 5 Step Knowledge Transfer process:

Prepare Me

Identify and notify the individuals to engage with the targeted Knowledge Transfer process.

Explain the process steps and methodology.

Show Me

Train the Principles, Systems and Tools related to the chosen subject matter. Demonstrate the

process and associated behaviours to the trainee [this is done at the Gemba, in the workplace

where the work is done].

Let Me

Let the trainee practise under guidance from the coach in a safe environment to apply their

learning and experiment with their behaviour and expected outcomes.

Support Me

Allow the trainee to stand alone in the application of the subject matter. The coach conducts

Process Confirmation to ensure the capability is embedded and sustainable.

Coach Me

Capability development is transferred to the incumbent organisation to ensure structured talent

management is ongoing and habitual. The preferred methodology is based around the TGROW

approach.

The TGROW approach encourages a structured, regular coaching dialogue with the trainee. It is

made up of 5 elements:

- Theme

- Goal

- Options

- Will to commit

- Reality

The project was implemented over a 10-month period, with specialist resources deployed relative

to the step. Step 1 took place during the first 3 months of the project. Step 2 took place during

months 2-4, while step 3 lasted from month 2 through to project completion at month 10.

39% increase in Sprint Period task completion

29% increase in milestone completion

31% reduction in days overrun (and 11% decrease in equivalent hours)

324:1 ROI

Lean Plant Leadership Programme

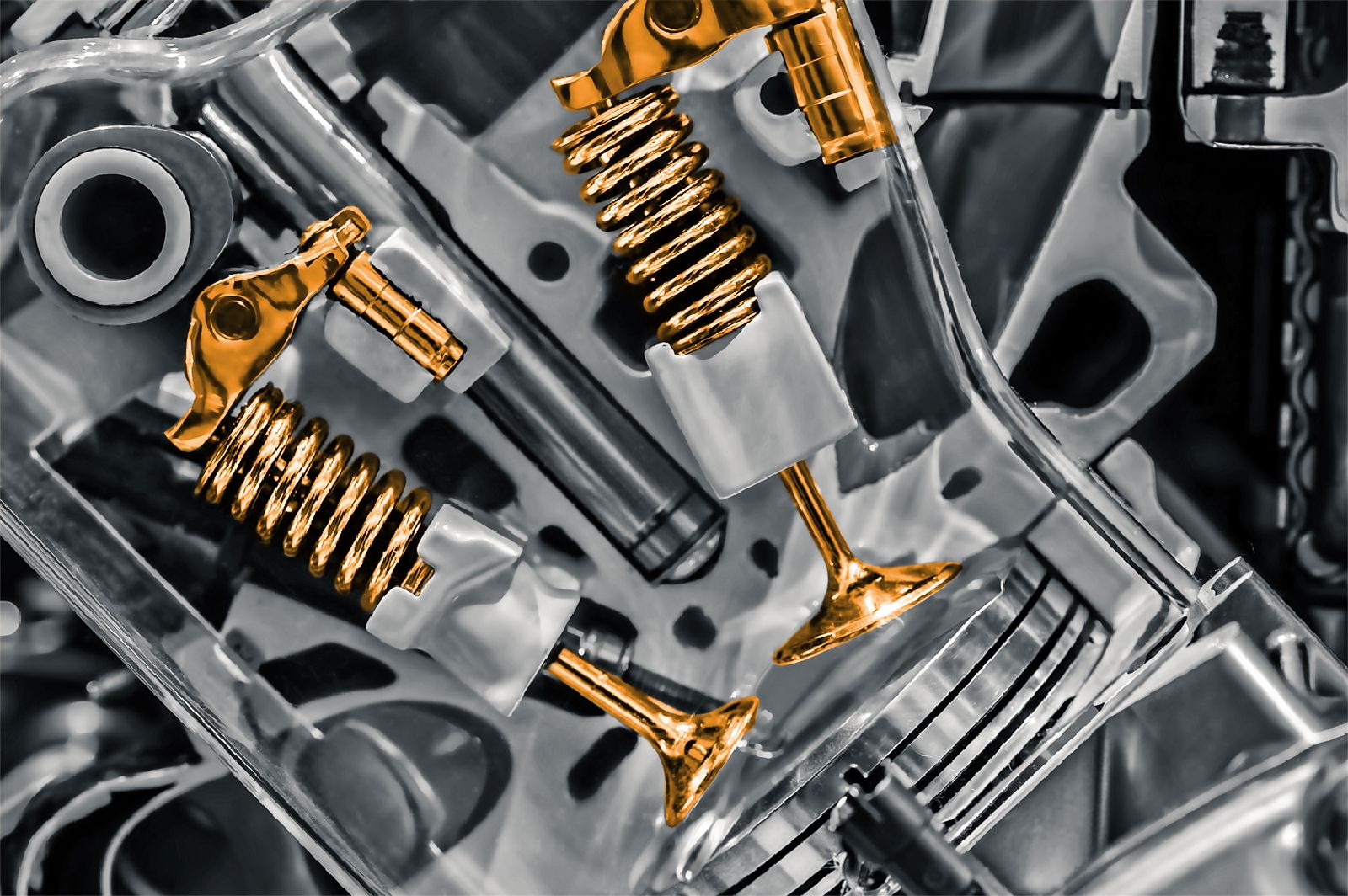

Our Client is one of the world’s largest and most respected first tier Engine Valve manufacturers in the automotive industry, supplying valves to most major car manufacturers, across the globe.

The vehicle engine components market has grown ever more competitive in recent years, with an increase in scrap rates and high levels of finished product, compounded by a decline in performance and increasing competition from low-cost manufacturers.

As such, our Client needed to identify new and improved processes to help increase and sustain performance. Project7 [P7] commenced engagement with the Client in 2009, with the aim of coaching and integrating a Lean Leadership Programme that would boost productivity and strengthen equipment reliability.

The company were facing significant challenges that stemmed from the lack of a clearly defined, standardised operating system throughout their plants. As a result, an inconsistent variation of processes, systems, product quality and delivery outputs existed – impacting negatively on customer confidence.

The Client desperately needed access to Lean tools & principles in order to create a standard foundation for business Operational Excellence, across their Engine Components division.

In order to improve business performance and tighten engineering processes, intervention from P7 needed to include;

- Creation of a standard foundation for Operational Excellence.

- Integration of an effective engineering maintenance process – to improve asset management and equipment availability.

- Identification of the right processes combined with the right people to achieve sustainable performance output.

This would be achieved via a Back to Basics approach focusing upon the core manufacturing business.

After assessing their options, the Client and P7 decided upon a solution; to create and deploy a Lean Plant Leadership Programme [LP2 ].

In order to overcome the key challenges, P7 were assigned with designing, implementing and evaluating a world class operating system that would be standardised and applied throughout their 14 manufacturing sites, on a global level.

This solution would enable the Client to deliver the required effective performance targets against safety, quality, delivery, cost and staff, through the creation of a high-performing team culture.

Project7’s proposed solution consisted of the seven steps of the P7 Way:

- Strategy into Action [Policy Deployment]

- Tiered Visual Performance Management [TVPM]

- Short Interval Control & Performance Dialogues

- Process Confirmation & Go Look See

- Setting Clear & Aligned Targets; Problem-solving Level 1

- Coaching for Success; Problem-solving Level 2

- Talent Management and Leadership Development

The team’s task was to adapt and implement these seven steps through the creation of a Lean Plant Leadership Programme, thus creating an Engine Components Operating System.

Project7 worked closely with the executive team to clearly define the Client’s needs. The performance improvements identified focused upon developing the organisation through the implementation of Lean techniques and best practice, across operations and engineering maintenance departments.

Within each site, a master schedule was created with the local sites leadership teams, which drove the activities that could be measured against performance [Operational Performance Rate]. Clear directional targets were then set out and processes created.

Each site had a 4-month implementation period for the delivery of LP2 , based upon our 3P approach.

- Interim Plant Management – Provision of Senior Management to take accountability for business turnaround.

- Capability – Talent management and knowledge transfer through 4 Step Knowledge Transfer methodology.

- Structure – Line back spans of control, structure, roles & responsibilities and visual demarcation, management by location.

- Yokoten – Global sharing of best practices including go look see.

- Governance – Tiered communication and governance schedules supported by Standard Delivery.

- Hoshin Kanri – Facilitation and development of annual strategy, tactics and objectives. Design and Implementation of the KPI tree and BSC.

- Tiered Visual Performance Management – Regular candid performance dialogues at all levels and functions to turn data into information, information into knowledge, make decisions, define the resulting actions and tangibly measure the results.

- Short Interval Control – Implementation of hour to hour controls, quality and performance measurement linked to escalation [evolving into Andon].

- Kaikaku – Design and implementation of new processes including TPM, PM regimes, Maintenance Satellite

- and Line Patrol to support OEE improvement and sustainability.

- Problem Solving – Local team 3C and systemic problem resolution training, implementation and integration into the structured governance system.

As a result of project support and implementations from P7, the Client has achieved significant improvements in business performance, including;

- 31% Improvement in Overall Equipment Effectiveness

- 4% Reduction in Scrap

- 67% Reduction in Premium Freight

- 7% Reduction in Temporary Resource

- 21% Reduction in Change Overtime, Hit to Hit

- 33% in Equipment Cycle Time [Bottleneck]

- $24m Cost Avoidance in Capital Investment

- 21% Reduction in Finished Goods Inventory

- 11% Reduction in Overtime

Pathology Service Improvement

UK Learning NHS Trust provides emergency and non-emergency services to East Surrey, NorthEast West Sussex and South Croydon. East Surrey Hospital, Redhill has 697 beds, and there are a range of outpatient, diagnostic and planned services at The Earlswood Centre, Caterham Dene Hospital and Oxted Health Centre in Surrey, and at Crawley Hospital and Horsham in West Sussex. In total there are circa 3,500 staff, with an annual budget of £300m.

The trust needed to reduce overall costs, as they had overspent by £20,000,000. They faced issues with processing samples and routine maintenance of analysers in the haematology and microbiology processing laboratories. Due to shift patterns and staff availability, this significantly impacted capacity.

The reception staff felt overworked and felt that sample delivery in the late afternoon was a problem due to cross-functional problems with the facilities department that owned the delivery and collection process. Additionally, there were issues with sample expedition from wards to the specimen reception by the porters. Many improvement initiatives had been tried, with limited success due to lack of involvement from the specimen reception staff, who felt these measures were imposed without their input.

At a first glance, the Pathology department appeared well organised and effective in the way they were processing samples through the specimen reception, however upon closer inspection, several issues were found.

Workload in the afternoon was excessive due to late delivery of samples from the local GP and clinics in the surrounding area. The hospital’s own A&E had many issues on the prioritisation of emergency samples.

Pathology reception staff were working well beyond contracted hours in order to process samples.

Additionally, porters were collecting samples from wards and delaying delivery to specimen reception by up to 2 hours, leading to degradation of blood samples.

The layout of the reception area did not have a logical process flow. Items and benches were positioned in available space, rather than considering the flow of the samples.

The booking in area was in a remote location in another room, which led to extra batching of samples to achieve an economical quantity that could be transported to reduce walking backwards and forwards.

Collection routes for facilities department were not matched to the times the pathology department

was available for processing samples. The driver’s routes were arranged around breaks and

lunchtimes, with a final return drop off at 16:00 to coincide with the end of the driver’s shift. This

led to uneven work flow and staff waiting for drop offs. As a result, centrifuges were under-utilised

and sat idle for extended periods waiting for the next bulk batch of samples to be delivered.

The specimen reception area was assessed and ways to improve the flow and expedition of samples through the area were planned. The area was rearranged according to these specifications.

A prioritisation system for samples was introduced to the A&E department of the hospital in order to address the issues around this area that slowed down delivery of samples.

In order to work better with both internal changes (such as driver timetables being moved) and external factors (eg. GP opening times), and as a result of the improvements in productivity, staff timetables were adjusted.

- 32% increase in throughput

- 65% reduction in excess work hours

- Last drop brought forward by 50 minutes

- 90 minute average improvement in time until results available to GPs and clinics

- Department reorganised to consider process flow

Pharmacy Service Improvement

UK Learning NHS Trust provides emergency and non-emergency services to East Surrey, NorthEast West Sussex and South Croydon. East Surrey Hospital, Redhill has 697 beds, and there are a range of outpatient, diagnostic and planned services at The Earlswood Centre, Caterham Dene Hospital and Oxted Health Centre in Surrey, and at Crawley Hospital and Horsham in West Sussex. In total there are circa 3,500 staff, with an annual budget of £300m. The trust needed to reduce overall costs, as they had overspent by £20,000,000.

Due to difficulty hiring and retaining professional staff, there were several vacancies remaining unfilled. This led a very high locum spend and reliance on bank staff to meet daily requirements.

The pharmacy was performing poorly against trust expectations and commitments, with consistently high levels of patients being discharged without their medication. This was leading to very high costs to deliver the medication via whatever means were available to the trust.

Morale in the dispensary was very low. Staff had improvement suggestions but were unable to implement their ideas due to crossover between departments such as portering and facilities.

A budget was made available to redesign the department if required, and the trust was willing to make any changes that it felt necessary. Value for money and clear business case evidence would be deciding factors.

This Pharmacy department had been confronted with numerous issues relating to the timely expedition of take-out medication for patients who had been discharged.

Staff were finding it difficult to process the prescriptions after the ward rounds, as they were arriving in bulk, late in the afternoon, and up to 700 Prescriptions were processed each day.

On many occasions, the medication would be delivered to the wards after the patient had been discharged. This was leading to significant amounts of medication being disposed of or being stored on wards.

Pharmacists did not take part in ward rounds and were consistently paged to screen drug charts at regular intervals, stopping them from carrying out their role effectively.

Medication to take out [TTO’s] were not being delivered in a timely manner, leading to extended length of stay for patients who should have been discharged.

The wait times in the Pharmacy varied widely. We discovered that this was because the pharmacy did not operate any kind of ‘first in, first out’ processing – the next prescription processed was the one on the top of the pile. This lead to very long delays for the prescriptions at the bottom of the pile.

No tracking of prescriptions was in place, no one knew if the specific prescription was in process

or at what stage. This lead to a lot of firefighting and searching when a prescription was being

chased.

We reviewed the Pharmacies establishment and identified any staffing requirements and levels of competency required to dispense in line with volume required.

A process mapping activity was undertaken with professional staff in order to identify areas where improvement opportunities existed.

In the Pharmacy dispensary, we identified the blockers to meeting the 2-hour turnaround required by the trust to meet required objectives. A review of the working practice needed to be undertaken in order to identify areas for improvement. Once we discovered there was no first come, first served system, we implemented this system. This vastly improved wait times. Additionally, short interval control was implemented within the pharmacy in order to manage variation in demand across the day.

In response to the issues with medication being delivered to the ward after the patient had already left, a Plan, Do, Check, Act confirmation system was implemented in order to confirm if the patient was present to receive drugs before departure, and storage of medications on the ward was no longer allowed.

- 59% reduction in turnaround time (reduced from circa 3.4 hours to within 2 hours)

- Department establishment defined with plan for implementation

- Headcount reduced by 3 substantive posts

- 70% reduction in Locum spend

- Tracker system introduced

- Standard delivery route and times introduced for porters