Quality as an Inclusive Culture

At Project7 Consultancy, we understand that quality is not just a department or a checklist; it is a culture that must permeate every level of an organisation. For senior leaders committed to driving excellence, fostering an inclusive quality culture is essential for long-term success and sustainability. Our approach combines industry best practices with insights from Dr Anthony Kenneson-Adams FIoL, a former Engineering Squadron Commander in the Royal Air Force (RAF), who is part of our senior leadership team. Anthony’s military background provides a unique perspective on how quality can be ingrained into the fabric of an organisation.

The Essence of Quality Culture

A quality culture is one where every individual, from top management to the frontline worker, is dedicated to maintaining the highest standards. It’s about creating an environment where quality is everyone’s responsibility and continuous improvement is a fundamental part of the organisational ethos. When we ask Anthony about what he feels are the three core elements to build and sustain quality as an inclusive culture, Anthony cites Training, Communication, and Commitment.

Training: The Backbone of Quality

In the RAF, even simple tasks like servicing anti-collision lights were critical to flight safety, demonstrating that quality starts with the basics,” says Anthony.

Effective training is the cornerstone of a robust quality culture. It equips employees with the knowledge and skills necessary to perform their tasks to the highest standards. Reflecting on Anthony’s military background, where training is rigorous and comprehensive, we emphasise the importance of precision and responsibility from the start.

- Customised Training Programs: Tailor training to meet the specific needs of your workforce.

- Continuous Learning: Encourage a culture of continuous learning. Regularly update training materials to reflect the latest industry standards and technological advancements.

- Practical Application: Ensure training includes practical applications. Hands-on experience reinforces theoretical knowledge and helps employees understand the real-world implications of their work.

Communication: The Key to Engagement

Open and effective communication is vital in fostering a quality culture. It ensures that everyone is on the same page and that potential issues are addressed proactively. In the RAF, Anthony learned the importance of open communication channels and the confidence to voice concerns without fear of retribution, which were critical in maintaining engineering quality standards.

- Transparent Channels: Establish transparent communication channels where employees feel safe to voice concerns and provide feedback without fear of retribution.

- Regular Updates: Keep the team informed about quality goals, progress, and any changes in procedures. Regular updates help maintain focus and alignment.

- Inclusive Dialogue: Promote an inclusive dialogue where ideas and suggestions are welcomed. Encourage employees at all levels to participate in discussions about quality improvements.

Commitment: The Foundation of Excellence

Commitment to quality must start at the top and cascade throughout the organisation. Leaders play a critical role in setting the tone and demonstrating their dedication to quality. In the RAF, there is no dedicated quality manager or department; instead, a culture of individual and collective commitment to quality permeated every rank and role. Anthony’s experience underscores the importance of this collective responsibility.

- Lead by Example: Senior leaders should exemplify quality in their actions and decisions. This sets a powerful precedent for the rest of the organisation.

- Integrated Quality Goals: Integrate quality goals into the overall business strategy. Ensure that quality is a key performance indicator for all departments.

- Empower Employees: Empower employees by providing the necessary resources and autonomy to make decisions that enhance quality. Trust and support from leadership foster a sense of ownership and responsibility.

Implementing Quality Culture in Your Organisation

Implementing a quality culture requires a strategic approach and consistent effort. Here are some steps senior leaders can take to embed quality into their organisation’s fabric:

- Assessment and Benchmarking: Start with a thorough assessment of your current quality practices. Benchmark against industry standards to identify areas for improvement.

- Strategic Planning: Develop a strategic plan that outlines clear quality objectives and the steps needed to achieve them. Ensure alignment with the overall business strategy.

- Engagement and Buy-In: Engage employees at all levels in the quality journey. Secure buy-in by highlighting the benefits of a quality culture, such as improved performance, customer satisfaction, and competitive advantage.

- Monitoring and Evaluation: Implement robust monitoring and evaluation systems to track progress. Regularly review and adjust strategies to ensure continuous improvement.

At Project7 Consultancy, we believe that an inclusive quality culture is the foundation of operational excellence. By focusing on training, communication, and commitment, senior leaders can transform their organisations and achieve sustainable success. Quality should not be seen as an isolated function but as an integral part of every process and decision.

By embedding these principles into your organisation, and drawing on insights from leaders like Dr Anthony Kenneson-Adams with a rich military background, you can drive performance, enhance customer satisfaction, and secure a competitive advantage in the marketplace.

Achieving Right First Time Quality in Lean Manufacturing

While lean methodologies emphasise process optimisation, the human element often proves to be the differentiating factor in achieving sustained quality improvements. This article suggests how effective utilisation of human capital will enhance overall quality outcomes and organisational performance. By highlighting the significance of empowering and engaging employees, this article contributes to a deeper understanding of the interplay between people and processes in lean manufacturing environments.

Amidst the emphasis on process optimisation, the role of people often tends to be overshadowed. The demands of employees for ethical and authentic leadership in a demonstrated culture of psychological safety and emotional intelligence in a developing world of Industry 5.0 is alien to many leaders, and confusing to others. This article aims to underscore the significance of people-centric approaches in driving right first-time quality outcomes within lean manufacturing frameworks.

Lean Manufacturing and Right First Time Quality

Lean manufacturing principles are centred on the relentless pursuit of perfection through waste reduction, continuous improvement, and the delivery of value to customers. While lean tools and techniques such as value stream mapping, 5S, and Kanban play a crucial role in streamlining processes and minimising defects, their effectiveness ultimately hinges on human involvement and decision-making to sustain the energy and intention of change. Employees are not merely cogs in the machine but rather active participants whose knowledge, skills, and commitment profoundly impact quality outcomes.

The Human Element in Lean Manufacturing

Firstly, let’s look at employee engagement. Engaged employees are more likely to take ownership of their work and strive for quality and operational excellence. For many years, the mantra has been “Treat people as you would expect to be treated,” this mantra has now changed to “Treat people as they expect to be treated.” This is not semantics but a very real need in 2024 and beyond to meet the expectations of Gen ‘Z’ and millennials in the workplace; I would argue that this should have always been so.

People expect to feel psychologically safe and heard in order to engage. They expect to contribute and have those contributions welcomed or at least be honestly and openly considered. Lean practitioners have always quoted one of the eight wastes in Lean as not using our people’s intellect, the difference now is that we must act on this awareness to retain our people; we have to put as much effort into our people as we do the established Lean tools. By fostering a culture of continuous improvement and providing avenues for employee involvement in problem-solving, organisations can harness the collective intelligence of their workforce to identify and address quality issues proactively.

Leadership and Communication

As a consultant I am asked to help businesses improve. Though this may be considered a bold statement, in probably 95% of the cases the issue that needs to improve always goes back to leadership. Effective leadership is instrumental in guiding teams towards quality objectives and fostering a shared sense of purpose. Clear communication channels facilitate the dissemination of quality-related information and enable employees to align their efforts with organisational goals, resulting in improved coordination and collaboration across departments; that is when the employees understand the goals, and the culture is such that the leadership removes the barriers in order that the employees can achieve the goals. But what I find so often is that middle level or even senior leadership have not been given the training, tools or skill sets by their leadership to be able to lead, to identify the goals, or how to remove the barriers by their leadership.

Leveraging Lean Tools with a People-Centric Approach

While lean tools and techniques provide valuable frameworks for process improvement, their successful implementation depends on the active involvement and commitment of employees at all levels of the organisation. For instance, implementing 5S principles requires not only rearranging workspaces but also instilling a culture of cleanliness and organisation through employee training and reinforcement, to sustain the change. Similarly, the success of a Kanban system relies on effective communication and collaboration among team members to ensure timely replenishment and movement of materials.

Dr W. E. Deming wrote about this in his 14 Principles of Continuous Improvement 70 years ago, which became the foundation of the famous Toyota Production System. Now even though the tools have been commonplace from his teachings for over half a century, how to get the best out of people is still not being held as having equal importance.

Conclusion

In conclusion, while lean manufacturing provides a structured approach to both quality and process optimisation, its effectiveness in delivering right first-time quality ultimately hinges on the active involvement, true engagement, and empowerment of people. By recognising employees as more than just ‘assets,’ but as enablers, and investing in their development, organisations can create a culture of quality excellence that permeates every aspect of their operations. It is imperative for organisations to strike a balance between process optimisation and people-centric approaches to maximise the benefits of lean manufacturing and drive sustainable quality improvements.

Continuous Improvement Leadership – Accelerating Your Success

Leadership of Continuous Improvement (CI) must be a constantly evolving field to meet the cumulative challenges of Leadership 4.0, the retirement of the last of the baby boomer generation, the rise of hybrid working, the difficulties of recruitment into manufacturing, industries where facilities still rely on break-down maintenance, increasingly competitive market sectors, reducing margins etc.

Though new leadership models are constantly coming in and out of fashion, when it comes to leadership of CI it is important to look behind the latest book or trend, deeply reflect on the true roots of CI Leadership and ask yourself am I prepared for the challenges of CI leadership in 2024 and beyond.

In this article that will explore CI leadership to its bedrock that precedes even the Toyota Production System (TPS), that is often credited as the origin of CI leadership, I will go back to the true father of quality and CI leadership, Dr W. E. Deming. In fact Taiichi Ohno the designer of the TPS, credited W. E. Deming with having a “Significant role in the development of the Toyota Production System.”

In this article I will discuss Demings’ 14 Principles for quality and continuous improvement leadership and show from my experience how each principle is not only relevant today, but also transformative in preparing for and upgrading current CI leadership for the challenges leading CI through 2024 and beyond.

Who Was W. E. Deming?

If you really want to get to know W. E. Deming you could do little better than reading his seminal work The New Economics For Industry, Government, Education. (1993). In this volume you will also learn how he further developed PDCA (Shewhart) cycle that so many of us hold as another pillar of continuous improvement.

Deming was a renowned American statistician, professor, author, lecturer, and consultant who won many prestigious awards including the National Medal of Technology that was awarded to him by President Reagan in 1987.

He is most renowned for his work in post-war Japan where he was largely responsible for teaching senior executives the methods of quality management through CI that dramatically altered the post-war economy of Japan, particularly in the automotive industry. It was in Japan in 1960 that the Emperor awarded Deming the Second Order Medal of the Sacred Treasure for exceptional contributions and outstanding service to the betterment of Japanese society.

In Japan Deming devised his fourteen principles which remain the bed rock of today’s CI models, even though many users are unaware that they originated with Deming 80 years ago.

Deming’s 14 Principles for ‘Leadership.’

Though I would not be so bold as to question the great man, I would offer the suggestion that we should think about these points today as those for leaders as opposed to managers. By this I mean that the west has become a more dynamic place where every individual wants to have a voice and where creativity and innovation are now encouraged from the ground up, rather than from the top down. This change needs to be led by individuals who can inspire and engage people i.e. leaders, rather than managers who establish and maintain the routine. Thus, let us think about Deming’s 14 points for CI leadership.

1. Create constancy of purpose for improving products and services: Organizations should have a clear and consistent long-term vision and commitment to improving their products and services (sic).

a. One area I see in many companies is the constant changing to the latest ideas or what my professor used to call trends from the latest ‘Airport Book.’ Change cannot be erratic and chaotic; change must be planned and implemented in a measured and additive way. Never talk about the new ‘big idea,’ but being respectful about the good that has gone before always speak about change as an evolution, the next stage of continuous improvement.

2. Adopt a new philosophy: Management should embrace a new way of thinking, shifting from a focus on short-term profits to a focus on long-term growth and quality.

b. Sadly, and usually when times get difficult, decisions are still made for short term gain that invariably bring long term pain. I have seen that when a large contract has been lost that the immediate reaction is to shed the work force, loosing valuable experience that almost invariably will need to be replaced in the future, sometimes in as little as a few months. Long term growth needs a workforce that feels valued, it is then that they will be truly engaged. When times are hard it is important for CI leaders to speak up for what is right for the long-term success of the business, not the short-term P&L.

3. Cease dependence on inspection: Relying solely on inspection to catch defects is inefficient and costly. Instead, build quality into processes from the start.

c. This is one area that I consistently see where businesses now are doing well. Quality Inspection in almost every case has been replaced with cultures of Quality Assurance. Occasionally I see temporary transition point auditing, but the pervading culture is usually ‘don’t accept poor quality, don’t produce poor quality and don’t pass on poor quality.’

4. End the practice of awarding business based on price alone: Select suppliers based on their ability to provide high-quality products and services, not just their price.

d. I see this as industry dependent overlaid with the reality of the cost of raw material. Another complicating factor in industries such as aerospace is the scourge of single source supply. If a manufacturer has a monopoly, then they ‘call the shots on price.’ I see far more competition in automotive and the pulp and paper industries so buyers can have more options to source the ‘best’ rather than the ‘only.’ That said, even recycled paper is now seen more as a commodity, so buyers often have little choice. However, if there is choice, cheapest is not always the lowest ‘full life’ cost.

5. Improve constantly and forever the system of production and service: Continuous improvement should be an ongoing effort, with processes continually refined and optimized (sic).

e. This is the heart of the leadership of CI. An attitude or culture of continuous improvement brings the biggest impact to the business. This is the core of the Project7 book ‘Tomorrow’s OpEx Today,’ which focuses on building a living culture of CI that sustains continuous improvement. When the teams are engaged and are driving short interval control, process conformation, constant root cause problem solving, Gemba etc, CI becomes a self-sustaining culture of constant optimisation and refinement where the role of leadership is simply to provide the vision and remove the barriers.

6. Institute training on the job: Provide employees with the necessary skills and training to perform their jobs effectively.

f. This was never more essential, as since the days of Deming apprenticeships and work-based training has taken a major hit, and only very recently has this started to be addressed. Each employee should have a formal improvement plan to build agility and a career path. Consider techniques such as ‘Participative Action Research in Teams’ (PART) as a force multiplier for your training success, aligned with a proactive policy of capturing the experience of your soon to be retirees to use this experience to set up training and mentoring programmes. These are also key programs to provide you with business continuity planning.

7. Adopt and institute leadership: Effective leadership is crucial for driving quality improvement throughout the organization.

g. Businesses need to have effective leaders who model company values and expectations, who foster diversity and who are given the tools to be successful. Again I see that the skills of leadership are often expected to happen more through osmosis than policy. Importantly leadership growth is not the sole responsibility of HR; in fact, I would say they have the minimum responsibility here. The MDs, GMs and Department heads have the responsibility to define what they need for leadership and to play an active part in the development and mentoring of that leadership. HR may help in selecting outside agencies to help build the framework for the training, but the ownership must be with the business not the consultant.

8. Drive out fear: Create an environment where employees feel safe to voice concerns and suggest improvements without fear of reprisal.

h. Psychological safety and emotional intelligence along with Authentic Leadership are essential to create and nurture an innovative and engaged workforce. Without exception, adopting these new disciplines always brings business results. There are still toxic businesses and toxic ‘bosses’ out there who ‘rule’ by fear. My advice if you find yourself in such a situation, begin your exit plan today, you deserve better.

9. Break down barriers between departments: Promote cross-functional collaboration and communication to improve processes and products.

i. I still see departments in business separated by metaphorical ‘walls.’ Foundry staff that will not speak to CNC machinists, painters that will not speak with welders, printers who will not speak to the people who mix their inks, wastepaper yard operations teams who do not speak to the paper machine operators. Business is improved every time these ‘walls’ are removed. How are they removed? In my opinion it starts simply with communication? Ask people what they need, give them an opportunity to contribute, ask why they do not speak up. It will sometime be through lack of opportunity, sometimes it is due to misunderstanding, or an incident that happened years ago, or ‘it is just the culture,’ etc. This is something leaders can change by simply taking the lead.

10. Eliminate slogans and exhortations: Remove motivational slogans and instead focus on creating systems that encourage intrinsic motivation and pride in work.

j. Gimmicks to not motivate, value and mission statements that are not the lived experience of the work force are damaging, promises broken destroy trust. Building a motivated work force takes leadership effort and is the primary day job. Leaders must create systems that work in an environment of respect and recognise that the team may know best. We all know this, so why is it not made a primary focus. Often, it is a case of the ‘squeaky wheel gets the most oil.’ Do not waste your time running around ‘putting out fires.’ Put your effort into creating systems and culture. Make it a priority on your daily Leader Standard Work and then hold yourself accountable. When the systems and culture are working, you will not need slogans or exhortations neither will you spend the day chasing the next fire.

11. Eliminate numerical quotas: Do away with arbitrary production targets and numerical goals, which can lead to poor quality.

k. I consulted in one company whose sole focus ‘as a production centre’ was producing tons. They were far less concerned that the tons were first quality or would command the highest price. They were actually quite proud of the fact that they had a steady income stream from second quality product. WIP was ten times more than what was required, and they were about to rent extra warehouse space to store even more ‘WIP,’ that was in fact off-quality product for re-work. By adopting a CI culture I reduced WIP by 40% and increased first pass yield by 15% in just 4 months. Focus had to be good tons and robust systems to sustain the change, not ‘tons at all costs.’

12. Remove barriers to pride in workmanship: Foster a sense of pride and ownership in employees’ work by allowing them to take pride in their contributions.

l. The primary role of any leader in a CI culture must be to set the vison and remove the barriers. Your people cannot have pride in their work if they are constantly hindered and frustrated by physical and metaphorical barriers. So how do you find out what the barriers are? There are many extremely useful statistical tools, but why not start by simply asking your teams what you can do to improve their day? They will be quite candid if you are courageous enough to ask the question, and many will even offer solutions just for being considered able to offer a solution. What you as the leader must reflect on after listening to their comments is to ask yourself “Am I a barrier?” If you are a barrier, then you have a positive data point for your own CI.

13. Institute a vigorous program of education and self-improvement: Encourage employees to continuously learn and develop their skills.

m. Invest in your people. In one plant where I was the quality leader, the teams wanted to do something for charity and to get to know each other outside of work, so the business decided to support a local food pantry. There was a cost, as the business paid the hourly rate when they were at the pantry as if they were at work. However, the forward-looking GM saw the value in building morale, team spirit and giving people the time to just get to know each other. The pay-off was that the teams brought these relationships back to the factory and new dialogue and opportunities were found that were not expected at the start of the scheme. Meet the point of need for all your people and look for the opportunities not the disadvantages.

14. Put everyone in the company to work to accomplish the transformation: Quality improvement should involve all employees at every level of the organization, not just a select few.

n. In the recently published Project7 Consultancy book, ‘Tomorrow’s OpEx Today,’ (2023) we specifically address the issue that continuous improvement is not just the responsibility of quality, maintenance, and operations but that the tools of CI and more importantly the culture that sustains CI must have input from all departments HR, Suppliers, Purchasing, Logistics, Finance, Customers etc. I have seen that when CI is implemented in each of these areas, the business benefits through a common vision and from speaking a common language. Everyone in CI leadership must as a priority look for opportunities in each department to show quick wins and move CI culture forward.

Conclusion

Deming’s 14 principles have been influential in the field of quality management and continuous improvement since the 1950s. They have been adopted by many organizations worldwide as a framework for achieving continuous improvement and importantly these principles are as key to business success today as they were 70 years ago, and they will continue to maximise the potential of business going forward. Key to this success is how CI is led and how that leadership builds an attitude and culture of continuous improvement, and it is not just about the tools and techniques it is just as much about all your people. Driving CI is about People + Processes to provide Performance and neither on its own will change or sustain business. Deming knew this 70+ years ago and I advocate that as leadership fashions come and go, that we hold fast to his principles to drive and sustain continuous improvement.

Driving Product and Service Quality Enhancement

In the pursuit of operational excellence, lean manufacturing principles have emerged as indispensable, guiding industry and commerce towards efficiency, cost-effectiveness, and, crucially, quality assurance. Project7’s recent survey shed light on the pivotal role of two essential tools in this pursuit: robust Standard Operating Procedures (SOPs) and Process Confirmation.

According to our survey results, 40% of respondents identified robust SOPs as the most important lean manufacturing tool for enhancing quality. SOPs serve as comprehensive guidelines, meticulously detailing every operational step. They standardise procedures, ensure consistency, minimize errors, and facilitate continuous improvement initiatives. By providing a structured framework, SOPs empower employees to execute tasks with precision and confidence, thereby reducing deviations and ensuring product or service quality.

In our survey, 35% of respondents emphasized the importance of process confirmation which verifies processes are being followed correctly ensuring quality at every stage of delivery. By confirming processes, organisations instil a culture of accountability and adherence to standards, ultimately enhancing overall quality.

The significance of our survey results extends across diverse industries and sectors and offers universal applicability.

In service industries, robust SOPs standardize customer interactions, ensuring consistent service delivery and enhancing customer satisfaction. Meanwhile, process confirmation can verify the accuracy and efficiency of service processes, guaranteeing high-quality service outcomes and building trust with customers.

In production environments, robust SOPs play a critical role in standardising manufacturing processes, reducing variability, and ensuring product quality and safety. Process confirmation further reinforces quality assurance by verifying adherence to SOPs and identifying opportunities for process optimization. For example, in a packaging plant where we implemented SOPs, Process Confirmations and RCPS we saw a 60% reduction in customer complaints in 18 months. This was a substantial return on the investment for training and implementing these proven principles.

The survey findings highlight the indispensable role of robust SOPs and process confirmation in driving quality across diverse operational settings. By leveraging these tools, organisations can establish a culture of excellence, enhance operational efficiency, and deliver products and services that consistently meet and exceed customer expectations. In today’s competitive landscape, embracing lean manufacturing principles is not just advantageous but essential for achieving sustained success, consistent quality, and maintaining a competitive edge.

Enhancing Profitability Through Value Stream Mapping

In today’s competitive industrial landscape, companies are under constant pressure to maximize efficiency, minimize waste, and continuously improve their processes in order to drive profitability. To meet these challenges head-on, many organisations are turning to Value Stream Mapping (VSM) as a fundamental tool in their continuous improvement arsenal.

In this article, I will discuss the practical application of VSM in driving continuous improvement

thinking and profitability and demonstrate the value of VSM from examples particularly but not exclusively in manufacturing that have reduced waste and thereby improved profitability.

VSM identifies and eliminates the 8 wastes within any process: waiting time, over production, rework, excess movement, excess processing, wasting people’s skills and intellect, too much inventory, and inefficient transportation.

Figure 1. VSM completed by trainees on the Project7 Manufacturing Excellence Programme.

Understanding Value Stream Analysis

Though originally developed for Lean manufacturing in the automotive industry, I want to make the

point that VSM is not just a tool for the manufacturing industry. Though I have primarily used the

tool to improve processes in manufacturing, I have also used VSM and seen it used very successfully

to reduce machine down times, reduce truck loading times from 2.5 hours to 40 minutes, reducing

the time in a finance department for end of month closing from 11 days to 4 days, reducing the process time for insurance claims, and even increasing the throughput of patients to better utilise

operating teams and operating theatre utilization in hospitals.

VSM provides a clear visualization as in Figure 1, of a process journey from inputs (e.g. raw materials,

patients, loading order received) to outputs (e.g. car off the production line, patient delivered to the

recovery suite, truck leaves the loading dock). VSM highlights all non-value-added steps and

bottlenecks that hinder efficiency and enables teams to remove these wastes, thus increasing

productivity and profitability.

The Team

If you want to get the very best solution out of a VSM exercise, you must have the right people on

the VSM team. This team needs to be those who carry out the process under change and who will

have to own the future state. These are the people who understand, map, problem solve, and

provide the sustainable solution. This is not an exercise for department heads locked away in a

conference room.

The Methodology

Firstly, if you are just starting out with VSM, don’t over complicate this process. I tell my clients and

course delegates (Figure 1.) that it is better to achieve an 80% solution when getting started than to

get bogged down in process and never complete. VSM has its purists and I salute them; however,

you do not need to be an expert to begin VSM; there is enough in this article to get you started and

to achieve results. If you are nervous about running your first VSM exercise, ask if there is already

someone in your organisation that can coach you until you feel confident to go solo. If you do not

have such a resource, you can call in a specialist. That said, you will learn a lot by just following the

simple process below with your VSM team:

1. Define the Scope.

Probably one of the most important pieces of advice that I can give is to take the time to clearly

define the boundaries of the value stream you want to map. So much time can be wasted looking at

external inputs and processes; being specific will increase your likelihood of success. Determining

exactly what you want to improve will save you time and frustration. For example, if you want to

improve the machining of a car part, don’t look at forging or distribution. Likewise too is you want to

improve the throughput of patients through an operating theatre, don’t spend time looking at the

maintenance of the anaesthetic equipment.

2. Identify the Current State.

Using the people who own and work with the current process, physically walk the process

observing and documenting every step involved. Gather data on cycle times, Work In Progress (WIP),

and other relevant metrics, having accurate data will save you time later. Lastly, identify all the

processes, activities, and people that are elements in the value stream.

3. Create a Current State Map.

Map a visual representation of the current state, including all the steps, processes, and information

flows. As in Figure 1., I recommend using simple Post-it notes on a sheet of brown paper to record

the process. Mapping onto a brown paper sheet is useful as the work can be rolled up if a room

needs to be cleared. The current state is mapped exactly as it is observed, with a single colour Post-It

note horizontally across the map, or different colours to represent actions by a single department.

Decide on a process that works for you and stick with it. Avoid every temptation at this stage to

reengineer the process or discuss reengineering; yes, you can collect ideas and place them under the

step in a different colour to refer to later, but at this stage just record what you see. Keep it simple.

Use standardized symbols and labels to represent different elements of the process such as a hard

copy work instruction, a computer process, transportation, or a face-to-face conversation or a phone

call. These symbols may already be in use in your organisation but if they are not, you will find

options as a result of an internet search. Write these symbols on the bottom right of each Post-it

note. Write the actual time it takes to complete an action onto the Post-It note. The sum of these

times is the first best estimate of how long a task should take without waiting time, etc.

Once the current state map is complete, make sure the team is in complete agreement

before moving on. It is always interesting to listen to the conversations at this point as

‘lightbulb’ moments occur such as “I never knew you did that,” or “I do that exact same

thing at the end of the process,” or a manager saying, “I have run this line for 5 years and

never understood how we got from step 5 to step 6.” You may also find that essential steps

are carried out successfully by experienced individuals without any written process or

instructions. Capturing these will help you provide for business continuity when the person

is on holiday, is promoted or retires. Again this is critical to efficiency and profitability.

4. Calculate Key Metrics.

Calculate relevant current state performance metrics such as cycle time, lead time, or completed

actions per hour. Make these as accurate as possible, ideally from direct observation. These will

help you measure savings when you have the future state metrics sustained as a result of the VSM

process. It is important to plan to measure the change as carrying out a VSM, pulling people away

from work for 1, 2, or 3 days costs money and time, and VSM is designed to reduce and not add to

your costs.

5. Identify Waste.

Analyse the current state map with the entire team to identify and categorize the 8 wastes. By

looking specifically for the 8, you will have a far better chance of driving them out as opposed to

some other less structured approach. For example, when running the finance department VSM we

found that not only was the same data being collected by two different departments, but also data

was being collected that had become redundant several months earlier. Specificity will bring

accuracy.

6. Develop the Future State.

Leave the current state map as it is and now duplicate the process steps using clean Post-It notes,

adding new steps, removing waste, redundancy, and parallel paths, etc., as you design future state

for the value stream. Keeping the old map will give you a constant reference to which to return for

reference. Your team once faced with how the current state works (or does not work), will very

quickly see how and where to make the necessary improvements. Using the Post-It notes now

allows you to move them around, add new ones, or subsume several steps at different locations into

one value added step. Go back to your scope definition and resist the temptation for ‘mission

creep’ i.e., stick to the defined scope. If you need to better understand the inputs and outputs of

your process, you could carry out a simple SIPOC exercise which I will not explain here but you can

find how to action a SIPOC from an internet search. Likewise, if you need to establish who is

responsible or just needs to be informed about a specific action, carry out a RACI exercise. Again,

you will find out how to do this from an internet search. Finally, remove or reduce identified wastes

and improve process flow and then set specific goals and objectives for the future state. This is your

VSM solution, agreed upon by the whole team, that drives out waste and improves profitability.

7. Develop an Action Plan.

Create a detailed plan for implementing the changes required to move from the current state

to the future state. Do this by defining each action with its agreed priorities for the improvement

opportunities. Importantly, state who is responsible for each action and agree on completion times.

8. Implement Improvements.

Execute the action plan making the necessary changes to the future state value stream. Then

monitor progress and continue to make adjustments particularly as new ideas for savings come to

light. Remember this is a continuous improvement exercise so do not become protective or

intractable over your first solution.

9. Re-calculate Key Metrics.

Once the process has had time to bed-in, observe, measure and re-calculate the current

state performance metrics to demonstrate the change and record the value of the mapping exercise.

These metrics are now the new daily targets.

10. Monitor and Sustain.

Continuously monitor the performance of the value stream against the new metrics. It is

important to ensure that improvements are sustained with Leaders Standard Work, Short Interval

Control, Process Confirmation, etc., and make further adjustments as required. VSM is costly in

terms of the team’s time, so respect that time by instituting robust sustaining tools and processes.

11. Share and Communicate.

Share the value stream map and improvement progress with all relevant stakeholders and

any similar operations in your business. In Lean, this is called Yokoten, the sharing of best practice.

Maximise the benefit of your VSM so all areas of your business can share what you have learned

about how to increase profitability by driving out waste.

Use the VSM to start a conversation and foster a culture of continuous improvement and learning. It

is also important to remember that particularly when starting out that VSM is a dynamic process,

and it may require multiple iterations to achieve the desired level of optimization and efficiency.

That is ok, it’s important for the team to learn and grow together to build both competence and

consistency.

Impact on Profitability

The impact of Value Stream Mapping on profitability cannot be overstated. By consistently and

rigorously applying VSM principles, organisations can experience several tangible benefits including:

- Cost Reduction: VSM identifies opportunities to eliminate waste, optimize resource

utilization, and reduce operational costs, leading to improved profit margins.

- Increased Productivity: Improved efficiency, reduced lead times, and a streamlined

production process can boost productivity, allowing companies to produce more with the

same resources. - Enhanced Quality: Identifying and addressing defects and process inefficiencies leads to

consistently better product quality and fewer costly rework or warranty claims. - Competitive Advantage: Continuously improving the value stream allows organisations to

adapt to changing market conditions more quickly, giving them a competitive edge in the

marketplace. - Customer Loyalty: Meeting and exceeding customer expectations through value stream

improvements can lead to higher customer retention and loyalty. I have even brought the

customer into this process to build relationships and demonstrate the importance of getting

‘it’ right for the customer.

Conclusion

Value Stream Analysis is a powerful tool for organisations looking to achieve continuous

improvement and increased profitability. By identifying and eliminating waste, enhancing efficiency,

and fostering a customer-centric culture, businesses can drive innovation and maintain a competitive

edge in today’s rapidly evolving industrial landscape. Embracing VSM as a cornerstone of continuous

improvement thinking can lead to long-term success and sustainable growth, making it an invaluable

asset for any industrial operation.

Importantly, you do not need to be an expert to use VSM or any of the tools of Lean to drive out

waste and increase profitability. You just need a group of people who want to improve business and

are willing to learn and have a go. Good luck.

Failed Business Metrics

Introduction – Failed Business Metrics

If the business metrics that you are putting your focus, time, and energy into are not driving your business then you must ask if those metrics are failing your business. A successful metric should be growing your business; that means improving your equipment reliability, increasing your customer base and improving customer experience, maximizing your output margin and profitability, and optimizing your workforce.

Metrics

Let me first define leading and lagging metrics:

Leading metrics are valuable because they can serve as early warning signs or predictive tools, helping organizations and individuals make informed decisions and take proactive actions to achieve desired outcomes or avoid undesirable ones. Lagging metrics are little more than ‘dead’ data.

Reality

The reality of what I see too often is that business focuses on the output or lagging metric, and when the metric falls short of goal, managers react with a raft of activity to try and ‘plug the leak’ without truly addressing the real issues. This can be everything from a root cause investigation to a reorganization, to focus groups, to the easiest option of firing a few people. But what has changed down the line if these actions were not focused on a leading metric? You are right, very little to nothing at all.

Don’t get me wrong, as a Lean OpEx consultant I have a passion for data and metrics, but they must be the right metrics; they must be leading metrics that drive and sustain business change.

Here are a few examples of how to turn the wrong metrics into the right metrics:

I worked with a company that were very proud that they were now accurately capturing ‘all their safety metrics’ and as a result were able to investigate ‘every’ safety incident and put into place mitigation to avoid ‘every’ accident. However, they were not capturing the near misses that research shows are the indicators of future accidents.

Another company was very happy that they had a proactive campaign that meant every employee has to capture 1 near miss per week (spot the problem with this one?) However, when I asked the store’s supervisor how many Band-aids were used in one year the answer across what was a very large production facility was around 2000. When I looked in the first aid log, I could only find 12 incidents that has needed a Band-aid. So which was true? The metric that gave the best picture was the storeroom Band-aid consumption rate; that was the true indicator of incidents, not the first aid log.

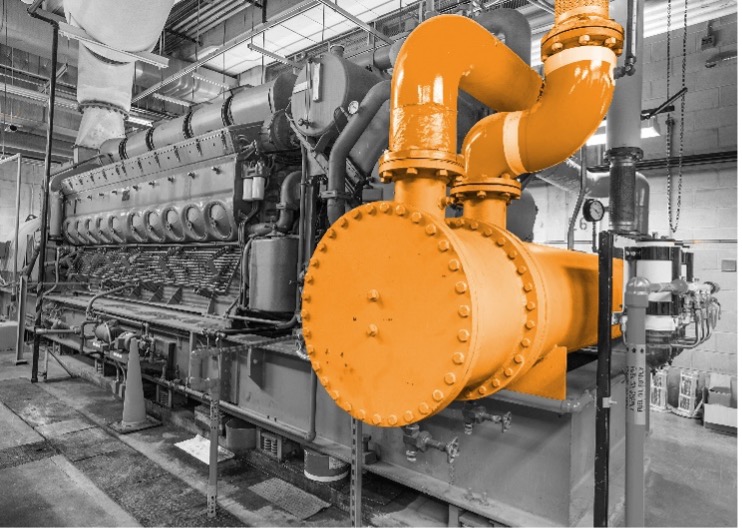

Reliability

The same story should be seen in reliability. What steps are being taken on input ‘leading’ business metrics rather than just publishing the output metric? Take Mean Time Between Failures (MTBF), there is little point publishing graphs of MTBF as a lagging metric if they are not driving change in input leading metrics to improve MTBF. If MTBF is poor, we have to look at training, quality of the equipment, servicing frequency, tool serviceability, test equipment calibration, personnel training and importantly the quality of SOPs and especially PMs and PdMs, etc. Focusing on the leading metric will directly impact the lagging metric.

Failed Business Metrics – Conclusion

If your metrics are little more than wallpaper, ask yourself if you are focusing on lagging rather than leading metrics. If your metrics are not driving your business, you are almost certainly not focusing on the right metrics to effect change.

The CMMS: Where Data Goes to Die – Unleashing the Potential of Your Maintenance Digital Backbone

In the bustling realm of modern manufacturing, where precision and efficiency reign supreme, the digital technology of Industry 4.0 plays a pivotal role. Among the myriad of tools and systems at a maintenance managers disposal is the Computerized Maintenance Management System (CMMS). The CMMS can be the digital backbone for maintenance, providing streamlined planning and execution, parts management, and data-driven decisions that importantly drive reduced downtime. Yet, for many manufacturing enterprises, the CMMS has earned a dubious reputation – as the place where data goes to die.

The Power of Data

We have learnt the lesson that as engineering and maintenance managers we need data. We have spent thousands of Dollars/Euros/Pounds implementing great data gathering Computerized Maintenance Management System. We have upgraded, added functionality, attached BOMs and listened to the evangelists for critical asset care, management of storeroom parts and data driven iterative maintenance management.

However, maintenance defects can still account for more than 30% of all machine lost time, and machine availability in the OEE equation can frequently be less than 60%. Maintenance departments are still too busy to fix a problem correctly the first time but invariably find time to shut down a machine for a second or third time until they eventually ‘find’ the fix. Lastly reacting to breakdowns in some businesses can expend more than 40% of maintenance person hours and cost the maintenance budget 4 to 15 times more than if data driven PMs or fault finding were used in the first place.

So what is going wrong? What I often see is that data is put into the CMMS almost as a comfortable place to rest and ‘die’, and all too often this data which is costly to collect has little or no effect on building reliability, driving OEE or building business profitability. The purpose of a CMMS is not as a repository but as a fuel tank to drive the engine of reliability.

Intelligent use of CMMS data is key to:

- PM design and ongoing optimization.

- Intelligent FRACAS.

- Business altering FME(C)A.

- Problem solving that is done once and once only.

- Building a data set as evidence for a business case for adding people or skills to the maintenance team.

- Driving machine availability e.g through Autonomous Maintenance.

- Improving business impacting OEE.

- Saving time across all the 8 wastes.

- Intelligent structuring of the maintenance team.

- Location of the Maintenance team and tool kits be that central and satellite locations and impact on MTTR.

- Future layout changes to optimise flow.

- Future equipment design.

- Purchase of additional maintenance equipment to reduce MTTR.

- Further technician training to reduce MTBF

- Optimisation of assets in the storeroom min/max levels, inventory value etc.

CMMS software is designed to capture and manage data to drive equipment reliability and impact business. If your CMMS is not being used to drive the list above you are not maximising the CMMS potential of exploiting its value to you as the Maintenance or Engineering Manager. When I take a look at how CMMS data is used by my clients that I see far too often that data underutilization is rife, and that data is metaphorically buried never to be seen again. So the simple message to my fellow maintenance professionals is that when it comes to the CMMS don’t bury data, be a data miner!

Reviving Computerized Maintenance Management System Best Practices

It’s time for maintainers to rethink their CMMS strategy and unlock its full potential. Here are three best practices to ensure that your CMMS becomes a data mine, rather than a data graveyard:

Budget and Time

A major change that is needed in implementing CMMS optimisation is provision of an ongoing budget to manage and train our people to interrogate and manipulate CMMS data. If our employees do not know how to add intelligence to the data to solve problems, then we can’t expect them to use that data to improve machine reliability. Plan time into the budget to train staff on FRACAS, 6 Sigma DMAIC, trend analysis, FMECA, and other established statistical and Lean tools that will exploit your collected data. A well-informed team is more likely to use the system effectively and consistently.

Set Clear Expectations

There should be a business expectation that data is a source to drive business. When leaders set the expectation, lead by example, and remove the barriers, then data driven business becomes a source for driving revenue and increasing margin.

Regularly Review and Refine Computerized Maintenance Management System Processes

Continuously evaluate your CMMS data interrogation and mining processes and adapt them as needed, such as to drive ongoing PM Optimisation. Solicit feedback from your team as to which area or equipment data should be analysed to identify areas for improvement. Use data to find and improve your top 10 unreliable pieces of equipment. CMMS data interrogation should be your first point of contact for improving machine reliability and continuous improvement.

Conclusion – Computerized Maintenance Management System Potential

The CMMS, once relegated to the shadows as the place where data goes to die, can become a beacon of efficiency and intelligence in building your machine reliability. To achieve this transformation, we as maintenance professionals must recognize that the CMMS is not just a data repository but a powerful tool for optimizing machine reliability.

By investing in training, integrating with cutting-edge tools and technologies, setting data entry standards, prioritizing data use and fostering a culture of data interrogation and continuous improvement, maintenance leadership can breathe life into their CMMS.

Only with use will your Computerized Maintenance Management System evolve from a stagnant data graveyard to a fuel tank to drive machine availability and operational excellence in the Industry 4.0 digital age.

The Leader’s Journey from Command and Control to Mission Command

Every maintenance leader has their own leadership style either by intent or nature. Here I consider two styles of leadership and make comparisons in their operation between military and industrial practice. Those two styles are ‘Command and Control’ and ‘Mission Command.’

The journey from command and control to mission command represents a major and sometimes difficult shift in management and leadership style.

Command and Control

Command and control refers to a hierarchical management style in which decision-making and control of information flows from the top down. This style of management can be effective in certain contexts, such as in military operations or in emergency response situations where swift and decisive action is needed. However, it can also stifle innovation and creativity, limit employee autonomy, and result in a lack of engagement and buy-in from team members.

Mission Command

In contrast, mission command is a more collaborative and decentralised approach to management that emphasises trust, autonomy, and shared purpose. In a mission command environment, teams make their own decisions and solve problems on their own, while still working towards a shared goal. Leaders in a mission command environment focus on facilitating communication and providing resources to support their teams. Having spent 30 years in the military I certainly saw command and control in action but a civilian reading this article may be surprised that we practised mission command rather than command and control whenever possible.

The Journey from Command and Control to Mission Command

The journey from command and control to mission command requires a fundamental shift in mindset, as well as a willingness to embrace new ways of working. This transition can involve changes in organisational structure, processes, and culture. It also requires leaders to adopt new leadership practices, such as active listening, coaching, and providing feedback. Having now spent 15 years in the civilian industry, I as a military veteran am often surprised at how often command and control operates on the shop floor rather than mission command and will take a few moments to reflect on why that might be.

Sink or Swim

Whether leaders sink or swim, in both the military and the civilian world is reliant on several factors amongst which are training and opportunity.

The civilian world does not seem to train leadership before appointments are made with one statistic putting the average age of leadership training in industry at 41-45 years old!

Is it any wonder then that the default method of command and control or ‘leadership by shouting’, is the self-perpetuating norm.

I can speak from experience that when in ‘live fire’ situations nobody is looking for a discussion on the pros or cons of taking cover and shooting back. Our immediate action is well-rehearsed, practised and refined; command and control is exactly what is needed. Command and control in this instance is a fallback built on instinct, necessity and an overwhelming sense of survival ensuring your team mate is safe even before considering your own safety. One of the team screams out “take cover,” and every team member does a duck and roll, opening fire on the enemy or awaiting the fire instruction.

In a safety situation in a paper mill I have used that same command and control to immediately shut down the machine if I see an unsafe condition, a missing safety guard, a broken light curtain or a technician working alone when they should have a safety watch.

But even in the military command and control is not the norm, it’s exhausting, demoralising and does not provide our soldiers, sailors and airmen with the experience, the headspace, to be able to think for themselves: which is vital in peace and war and in both military and civilian life.

More interesting then, is why so many leaders in industry adopt command and control as a primary style when no one is being shot at and everyone is safe. In large part I think that this is due to a fundamental difference between military leaders and shop floor leaders. As a 16 year old in basic training I was being taught about leadership and followership long before I began my engineering training. In fact, if a recruit did not pass leadership training they would be ‘shown the door’ without any chance of beginning engineering training. So, Leadership came first.

Now I am not saying that we should train our technicians to be leaders before they start an apprenticeship or join our company but, we should be providing leadership opportunities throughout a technician’s career and certainly be providing leadership training before we promote them to be supervisors or managers with leadership responsibilities. We would not let a technician carry out a job if they were not trained or certified in that task but we will let them lead others without preparing them to be successful. Industrial experience is replete with stories where poor leadership has caused people to be hurt or worse, so why the reticence to spend some budget money on training our people to lead.

Once we passed leadership in the military we were then given opportunities to practise leadership under as realistic a scenario as possible. Likewise, if we do not give our people opportunities to raise their game and practice leadership before they get into a leadership position then how can they be ready for the responsibilities of leadership?

How can they promote physical and psychological safety if they do not get the training and opportunity?

Climate Control

Providing for the application of mission command on the shop floor is what I think of as Climate Control. That is the responsibility of leadership to control an organisational climate, wherein people are provided with the opportunities to practise leadership, where they are coached not told, where there is a climate of learning in a safe environment so that when they are put into the position of leadership they are somewhat prepared to know how leadership ‘feels.’

The move from command and control to mission command is not easy, but this change consistently results in better leaders with greater employee engagement, more innovation, and increased productivity. Climate control can also help organisations to better adapt to a rapidly changing business environment and better serve their customers. However, this transition does not happen by accident and takes planning, training, and opportunity.

If we want great companies we need great leaders and that always starts with you and me.

Effective Strategies for Management of Critical Spare Parts and Stocks

Working closely with storeroom and purchasing leadership is essential to determine asset criticality and managing spare parts inventory. The goal is to maintain high OEE through availability and optimum process speed while minimising inventory value. Often, excess inventory ties up capital while critical components are lacking.

Here are effective strategies to build a robust critical asset and inventory management process:

Conduct an Asset Criticality Assessment

- Identify assets with the greatest impact on production and maintenance costs. Consider factors like function, process criticality, failure history and failure impact.

- Assign a criticality ranking to each asset:

- Criticality 1 – Shuts down entire plant or multiple lines

- Criticality 2 – Shuts down one line

- Criticality 3 – Slows production

- Focus time, effort and money where it will achieve the best ROI.

Perform Failure Mode Analysis

- Do Failure Mode and Effects Analysis (FMEA) on critical assets. Identify potential failure modes, causes and consequences.

- Prioritise assets based on failure severity and likelihood.

- Alternatively, leverage existing failure data to build a Failure Reporting and Criticality Analysis (FRACAS) database. FRACAS supports proactive failure management, reducing downtime and costs.

Analyse Reliability Data

- Analyse historical maintenance data and reliability metrics like MTBF, MTTR.

- Identify failure patterns and critical spares for frequently failing or long lead time components.

Classify Spare Parts

- Categorise spare parts as critical, essential or non-critical:

- Critical – Required to restore asset/line functionality promptly

- Essential – Necessary but may have longer lead times

- Non-critical – Readily available or minimal production impact

Evaluate Spare Part Availability

- Consider availability, lead time, supplier reliability and cost for each critical spare.

- Prioritise spares with higher failure probability or long lead times.

Optimise Inventory Levels

- Determine appropriate stock levels based on asset criticality, failure rates and lead times.

- Implement inventory techniques like JIT and min/max to balance availability and excess inventory.

Build Supplier Relationships

- Foster supplier relationships and service agreements to enable prompt delivery of critical spares.

Continuously Review and Optimise

- Regularly review assets, inventory and strategy based on updated data and operational changes.

- Continually align maintenance strategy to business needs.

Set Minimum and Maximum Levels

To establish component min/max levels:

- Analyse historical usage, lead times and failure data. Understand consumption rate, frequency and lead times.

- Calculate reorder point (ROP) based on lead time demand and safety stock to account for uncertainties.

- Set minimum level above ROP to avoid stockouts before replenishment.

- Determine maximum level based on storage space, costs of excess inventory and other factors.

- Prioritise levels based on component criticality.

- Optimise using techniques like EOQ, JIT and MRP.

- Maintain inventory accuracy through disciplined removal tracking.

- Continuously monitor, review and adjust levels based on changing requirements.

The criticality of assets and required spares evolves over time. Maintain ongoing evaluation and adjustment to align your strategy with business needs. Setting stock levels is an iterative process requiring discipline, data analysis and refinement based on circumstances.

Embarking on the Path to Operational Excellence

Operational Excellence is the ongoing practice of enhancing business operations to achieve superior performance and efficiency. Here are the steps to guide you on your own path towards operational excellence:

- Define your objectives: Before initiating any improvement efforts, it’s important to establish your aims and objectives clearly. What do you want to accomplish? What are the key performance indicators (KPIs) that will evaluate success?

- Identify areas for improvement: With a clear understanding of your objectives, you need to pinpoint the aspects of your business that require enhancement. This may involve scrutinising your current processes and systems to identify inefficiencies or opportunities for optimisation.

- Develop a plan: After identifying areas for improvement, you must devise a plan to achieve your objectives. This plan should encompass specific goals, timelines, and metrics for monitoring progress.

- Implement the plan: With a plan in place, it is time to begin implementing it. This might involve altering your processes, systems or organisational structure.

Small incremental changes contribute to significant changes over time!

- Monitor progress: As you carry out your plan, it is essential to observe progress and evaluate results against your KPIs. This will enable you to identify areas that are functioning well and those that might need further enhancement.

- Continuous improvement: Operational Excellence is an ongoing process, with ample room for improvement. Ensure that you persistently monitor and analyse your processes and systems to identify additional optimisation opportunities.

- Trusted Partner: If your organisation lacks an Operational Excellence expert on staff, expedite your programme and significantly increase your likelihood of success by collaborating with a trusted partner who will guide you through this intricate cultural shift.

The Unilever Case

To understand how these steps plan out in reality, let’s take a look at how Unilever approached its journey to Operational Excellence.

Unilever’s OpEx success can be attributed to its implementation of the Total Productive Maintenance (TPM) methodology, which emphasises efficiency and effectiveness in manufacturing.

Unilever faced challenges in managing the complexity of its vast product portfolio and maintaining a competitive edge in the market. To overcome these hurdles and achieve operational excellence, the company embraced TPM as part of its broader continuous improvement strategy.

Unilever outlined specific objectives, such as reducing downtime, minimising waste, and increasing overall equipment effectiveness (OEE).

The company then analysed its processes and systems to identify inefficiencies and areas requiring optimisation, such as equipment maintenance and production line workflows.

Unilever then created a comprehensive plan, including setting goals, timelines, and KPIs, to track the progress of its TPM implementation, before rolling out the TPM programme across its global manufacturing facilities, involving employees at all levels in problem-solving and improvement initiatives.

The company regularly monitored progress, evaluating results against KPIs, and adjusting the plan as needed to ensure continuous improvement. Unilever maintained its commitment to TPM, embedding a culture of continuous improvement throughout the organisation. This ongoing effort has resulted in further optimisation of processes and systems over time.

Not one to go it alone, Unilever collaborated with TPM consultants and experts, leveraging their expertise to facilitate the implementation process and ensure the successful adoption of TPM principles.

As a result of embracing TPM and operational excellence, Unilever has achieved significant improvements in efficiency, waste reduction, and overall productivity. This commitment to continuous improvement has enabled the company to remain competitive and maintain its position as a leading consumer goods manufacturer.

Key Takeaway

Remember that operational excellence is a journey, not a destination. It requires a commitment to continuous improvement and a willingness to adapt and evolve as your business grows and changes.

Project7 Consultancy are acknowledged experts in partnering with manufacturers to ensure they achieve sustainable success in their journey to Operational Excellence. Save time in achieving your success by speaking with us today.